Capability Statements

A One-Stop Shop for All Metal Parts Manufacturing

Big Orange Aerospace can assist you with both component design and the manufacture of high-quality finished metal parts and assemblies in various materials and to your specifications. We operate our own pre-treatment and finishing plant to ensure quality control and we also maintain close working relationships with sub-suppliers for specialist treatment services.

At Big Orange Aerospace we are continuously working on our processes, internal systems and technology to provide our customers with a rapid response, transparent communication, quality and cost control, as well as reliable delivery times.

At Big Orange Aerospacewe are continuously working on our processes, internal systems and technology to provide our customers with a rapid response, transparent communication, quality and cost control, as well as reliable delivery times. Our production planning system is state-of-the-art, and together with a great manufacturing team we are able to support customers with both low volume prototyping requirements and production runs at scale, in a wide range of materials including stainless steel, aluminum, nickel, bronze, brass, and copper

Our manufacturing services are flexible and based upon customer requirements. These include straight laser cutting and the supply of flat packed components, to the production of parts which are formed through several further processes such as bending, folding, punching, welding, and incorporate full assembly where required.

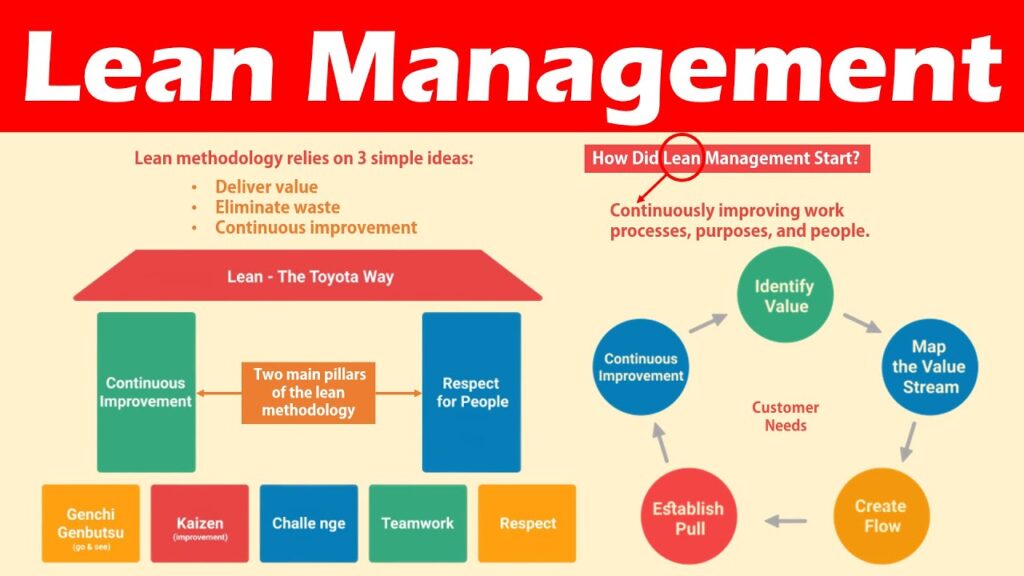

Smart Manufacturing Leveraging LEAN Production Principles

Our services include design, engineering, prototyping and testing, laser cutting, marking, punching, machining, bending and folding, welding, pre-treatment, finishing and assembly. We coordinate all aspects of your project to ensure quality control, value and peace of mind.

Using the latest in computer software, our engineering team collaborates with you to design and test detailed virtual prototypes that meet your exact specifications. Our design approach aims to maximise efficiency, and minimise cost and waste.

We offer full assembly of multiple individually manufactured components undertaken by our experienced and dedicated assembly line team. Components are combined to your precise specifications and the final assembly is carefully packed for shipping.

WHAT MAKES US DIFFERENT

Unlike other metal fabrication firms, Big Orange Aerospace Group offers a fully integrated, in-house design, metal engineering, fabrication and finishing service. This allows us to retain complete control over every aspect of the manufacturing process to deliver high-quality, precision-perfect components with reduced supply chain lead times and transaction costs.

We believe in honesty, transparency and open communication, taking full responsibility for every project. Our honesty and proactive approach help build the trust upon which our client relationships are based. Using our extensive experience and depth of knowledge, we also participate in thought leadership discussions and are contributing members of several industry working groups.

Our people are dedicated specialists. They bring their positive attitude, passion and considerable experience to their work every day and are key to our success. What’s more, their unwavering level of commitment ensures we meet the highest standards, while taking full responsibility for the work we produce

We Follow Best Practices

- Sustainablility

- Project On Time

- Modern Technology

- Latest Designs