Approach

At Big orange Aerospace, we use a seven-step process to consistently deliver complete metal engineering, fabrication and finishing solutions for our clients across all industry sectors.

Concept Assessment

Big Orange Aerospace offers precision metal cutting services using advanced

cutting technologies such as laser cutting, waterjet cutting, or plasma cutting.

They cater to a wide range of industries, including automotive, aerospace,

construction, manufacturing, and more.

Big Orange Aerospace has a state of the art facility equipped with modern

cutting machinery and tools. Their team of skilled technicians and engineers

ensures accurate and efficient metal cutting, whether it’s for custom parts,

prototypes, or large-scale production. They can work with various types of

metals, such as steel, aluminum, stainless steel, and alloys.

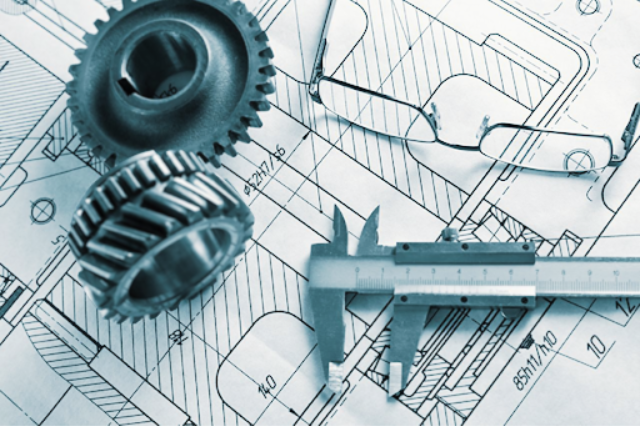

Design

Big Orange Aerospace Company understands that each project may require

unique and custom metal designs. They offer customization options to tailor the

design to specific dimensions, finishes, and features. This allows clients to have

metal designs that align with their branding, aesthetic preferences, and

functional requirements.

Once the design concept is approved, Big Orange Aerospace Company’s

engineering team converts the design into detailed technical specifications. They

consider factors such as structural integrity, material selection, manufacturing

processes, and industry regulations.

Testing

Big Orange Aerospace Company implements comprehensive quality control

measures throughout the production process. This includes rigorous inspections

of raw materials, intermediate components, and finished products. Quality

control checks help identify any defects, inconsistencies, or deviations from

specifications, ensuring that only high-quality metal products are delivered to

customers.

epending on the specific metal products being manufactured, Big Orange

Aerospace Company conducts performance testing to assess their functionality,

durability, and adherence to industry standards.

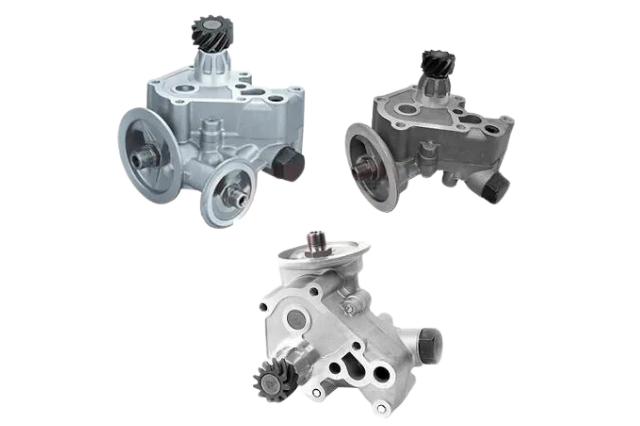

Production

Big Orange Aerospace Company begins with a comprehensive production

planning phase. This involves analyzing customer orders, forecasting demand,

and determining the required production capacity. The planning team considers

factors such as material availability, resource allocation, and production timelines

to create an optimized production plan.

To ensure smooth production operations, Big Orange Aerospace Company

effectively manages its resources. This includes human resources, machinery,

equipment, and raw materials. The company maintains a skilled workforce and

regularly invests in modern machinery and technology to enhance production

efficiency.

Finishing

Big Orange Aerospace Company offers various surface treatment options to

enhance the appearance, durability, and corrosion resistance of their metal

products. This may include processes such as sandblasting, polishing, grinding, or

brushing to achieve the desired texture and finish. Surface treatments also

prepare the metal surface for subsequent coatings or finishes.

Big Orange Aerospace Company provides coating and painting services to protect

metal products from corrosion, wear, and environmental factors. They use

different coating techniques, such as powder coating or liquid painting, to apply

protective layers onto the metal surfaces

Assembly

Big Orange Aerospace Company offers various surface treatment options to

enhance the appearance, durability, and corrosion resistance of their metal

products. This may include processes such as sandblasting, polishing, grinding, or

brushing to achieve the desired texture and finish. Surface treatments also

prepare the metal surface for subsequent coatings or finishes.

Big Orange Aerospace Company provides coating and painting services to protect

metal products from corrosion, wear, and environmental factors. They use

different coating techniques, such as powder coating or liquid painting, to apply

protective layers onto the metal surfaces.

Logistics

Big Orange Aerospace Company employs various assembly techniques based on

the specific requirements of the metal products. This may include mechanical

fastening methods such as welding, bolting, or riveting. Adhesive bonding or

soldering techniques may also be utilized when appropriate. Skilled technicians

and operators perform the assembly processes with precision and attention to

detail.

To ensure accuracy and consistency during assembly, Big Orange Aerospace

Company uses jigs, fixtures, and specialized tooling. These aids help position

components correctly, maintain alignment,and facilitate efficient assembly.